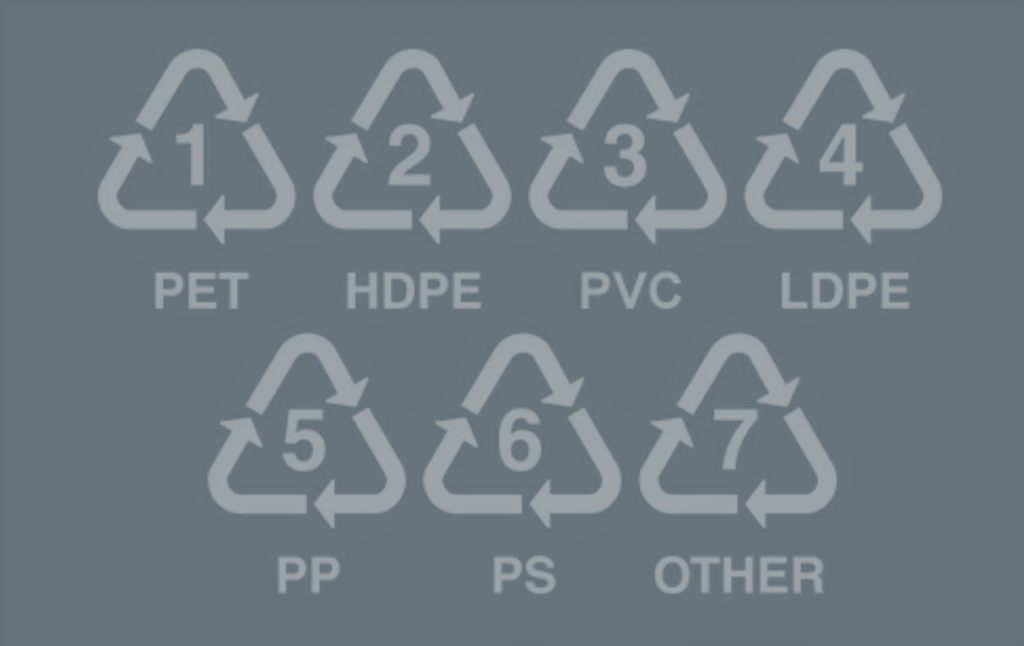

HDPE plastic is the stiff plastic used to make milk jugs, detergent and oil bottles, toys, and some plastic bags. HDPE is the most commonly recycled plastic and is considered one of the safest forms of plastic. It is a relatively simple and cost-effective process to recycle HDPE plastic for secondary use.

HDPE plastic is very hard-wearing and does not break down under exposure to sunlight or extremes of heating or freezing. For this reason, HDPE is used to make picnic tables, plastic lumber, waste bins, park benches, bed liners for trucks and other products which require durability and weather-resistance.

Products made of HDPE are reusable and recyclable.

PET is one of the most commonly used plastics in consumer products, and is found in most water and pop bottles, and some packaging. It is intended for single use applications; repeated use increases the risk of leaching and bacterial growth. PET plastic is difficult to decontaminate, and proper cleaning requires harmful chemicals. Polyethylene terephthalates may leach carcinogens.

PET plastic is recyclable and about 25% of PET bottles in the US today are recycled. The plastic is crushed and then shredded into small flakes which are then reprocessed to make new PET bottles, or spun into polyester fiber. This recycled fiber is used to make textiles such as fleece garments, carpets, stuffing for pillows and life jackets, and similar products.

Products made of #1 (PET) plastic should be recycled but not reused.

Polypropylene plastic is tough and lightweight, and has excellent heat-resistance qualities. It serves as a barrier against moisture, grease and chemicals. When you try to open the thin plastic liner in a cereal box, it is polypropylene. This keeps your cereal dry and fresh. PP is also commonly used for disposable diapers, pails, plastic bottle tops, margarine and yogurt containers, potato chip bags, straws, packing tape and rope.

Polypropylene is recyclable through some curbside recycling programs, but only about 3% of PP products are currently being recycled in the US. Recycled PP is used to make landscaping border stripping, battery cases, brooms, bins and trays. However, #5 plastic is today becoming more accepted by recyclers.

PP is considered safe for reuse. To recycle products made from PP, check with your local curbside program to see if they are now accepting this material.

PVC is a soft, flexible plastic used to make clear plastic food wrapping, cooking oil bottles, teething rings, children’s and pets’ toys, and blister packaging for myriad consumer products. It is commonly used as the sheathing material for computer cables, and to make plastic pipes and parts for plumbing. Because PVC is relatively impervious to sunlight and weather, it is used to make window frames, garden hoses, arbors, raised beds and trellises.

PVC is dubbed the “poison plastic” because it contains numerous toxins which it can leach throughout its entire life cycle. Almost all products using PVC require virgin material for their construction; less than 1% of PVC material is recycled.

Products made using PVC plastic are not recyclable. While some PCV products can be repurposed, PVC products should not be reused for applications with food or for children’s use.

LDPE is often found in shrink wraps, dry cleaner garment bags, squeezable bottles, and the type of plastic bags used to package bread. The plastic grocery bags used in most stores today are made using LDPE plastic. Some clothing and furniture also uses this type of plastic.

LDPE is considered less toxic than other plastics, and relatively safe for use. It is not commonly recycled, however, although this is changing in many communities today as more plastic recycling programs gear up to handle this material. When recycled, LDPE plastic is used for plastic lumber, landscaping boards, garbage can liners and floor tiles. Products made using recycled LDPE are not as hard or rigid as those made using recycled HDPE plastic.

Products made using LDPE plastic are reusable, but not always recyclable. You need to check with your local collection service to see if they are accepting LDPE plastic items for recycling.

Polystyrene is an inexpensive, lightweight and easily-formed plastic with a wide variety of uses. It is most often used to make disposable styrofoam drinking cups, take-out “clamshell” food containers, egg cartons, plastic picnic cutlery, foam packaging and those ubiquitous “peanut” foam chips used to fill shipping boxes to protect the contents. Polystyrene is also widely used to make rigid foam insulation and underlay sheeting for laminate flooring used in home construction.

Because polystyrene is structurally weak and ultra-lightweight, it breaks up easily and is dispersed readily throughout the natural environment. Beaches all over the world have bits of polystyrene lapping at the shores, and an untold number of marine species have ingested this plastic with immeasurable consequences to their health.

Polystyrene may leach styrene, a possible human carcinogen, into food products (especially when heated in a microwave). Chemicals present in polystyrene have been linked with human health and reproductive system dysfunction.

Recycling is not widely available for polystyrene products. Most curbside collection services will not accept polystyrene, which is why this material accounts for about 35% of US landfill material. While the technology for recycling polystyrene is available, the market for recycling is small. Awareness among consumers has grown, however, and polystyrene is being reused more often. While it is difficult to find a recycler for PS, some businesses like Mailboxes Etc. which provide shipping services are happy to receive foam packing chips for reuse.

Polystyrene should be avoided where possible.

The short chains containing the nitrile monomers bond together, making it stronger than polystyrene. Styrene gives the plastic a hard, shiny surface and butadiene, which is a rubber, makes it resilient. As a result, ABS is a lightweight, tough, rigid thermoplastic that has high impact and high mechanical strength.

HIPS is a low cost plastic material that is easy to machine and fabricate. HIPS is often specified for low strength structural applications when impact resistance, machinability, and low cost are required. … Natural (translucent white) HIPS is FDA compliant for use in food processing applications.